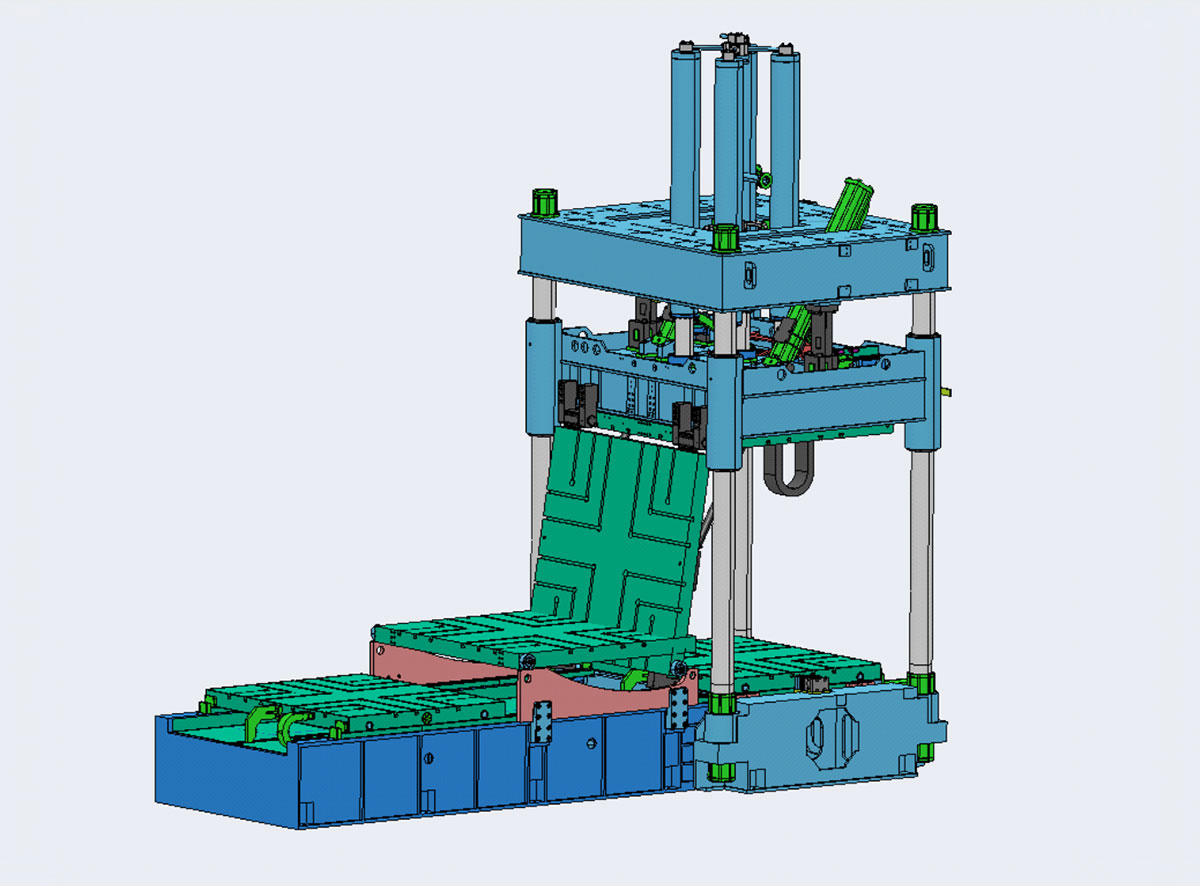

HUD Series Mold Closing Machine

Features:

1. All moving parts adopt graphite copper sleeve self-lubricating design, oil-free self-lubrication, cleaner and more environmentally friendly.

2. Four mold closing oil cylinders are used to distribute pressure more evenly, ensuring more reliable mold engagement with minimal deformation.

3. The equipment has practical and reliable fault detection,alarm, and safety protection functions.

4. The slider adopts stepless locking device, allowing locking at any point on the slider, providing higher safety and human-machine interaction.

5. The upper mold base can rotate 180°, significantly optimizing the practicality of the equipment, making the mold closing machine more ergonomic during use.

6. The lower workbench is equipped with a hydraulic lifting device and a high-precision moving positioning device, allowing precise movement of the lower mold base in and out.

7. The movement of the upper mold base is controlled by high-precision digital displacement sensors, ensuring more accurate positioning.

8. Adopting oil-electric servo system,the main oil pump controls speed and pressure through servo motor and servo control system, automatically matching oil pump speed according to the requirements of each step, reducing energy consumption and hydraulic oil loss in conventional systems caused by motor idling and throttling overflow. The oil-electric servo system has sensitive and rapid dynamic response,smooth speed switching, low impact,low power noise,and energy-saving and emission reduction benefits.

Technical Parameters:

| No. | Content | Model | ||||||||||||

| HUD 80/108 |

HUD 120/1411 |

HUD 160/1613 |

HUD 2000/1815 |

HUD 320/2218 |

HUD 400/3020 |

HUD 500/3020 |

HUD 500/3025 |

HUD 630/3525 |

HUD 630/4025 |

HUD 630/4030 |

||||

| 1 | Mold Closing Force/kN | 800 | 1200 | 1600 | 2000 | 3200 | 4000 | 5000 | 5000 | 6300 | 6300 | 6300 | ||

| 2 | Mold Opening Force/kN | 220 | 250 | 380 | 450 | 560 | 800 | 1200 | 1200 | 1500 | 1500 | 1500 | ||

| 3 | Mold Base Dimensions | Left-Right/mm | 1000 | 1400 | 1600 | 1800 | 2200 | 3000 | 3000 | 3000 | 3500 | 4000 | 4000 | |

| Front-Back/mm | 800 | 1100 | 1300 | 1500 | 1800 | 2000 | 2000 | 2500 | 2500 | 2500 | 3000 | |||

| 4 | Lower Mold Base Load Capacity/T | 4 | 8 | 16 | 20 | 36 | 50 | 60 | 60 | 70 | 80 | 90 | ||

| 5 | Max Opening Height/mm | 1200 | 1500 | 1700 | 1900 | 2300 | 2500 | 3000 | 3000 | 3200 | 3200 | 3500 | ||

| 6 | Max Slider Stroke/mm | 1000 | 1300 | 1500 | 1700 | 2100 | 2100 | 2600 | 2600 | 2800 | 2800 | 3100 | ||

| 7 | Working Speed/mm/s | 10-20 | 10-20 | 10-20 | 10-20 | 10-20 | 10-20 | 10-20 | 10-20 | 10-20 | 10-20 | 10-20 | ||

| 8 | Installed Power/kW | 11 | 15 | 18.5 | 22 | 30 | 45 | 55 | 55 | 74 | 74 | 74 | ||

Customization is available according to user or process requirements.